PVD Young Makers and Turnaround Arts: Providence Programs Pivot to Meet the Moment

PVD Young Makers Interns Utilize Minecraft to Create Community Connection in the Digital Realm

In mid-March, just as the COVID-19 pandemic approached the United States, PVD Young Makers student interns and staff learned of The Uncensored Library, Reporters Without Borders’ “attempt to circumvent censorship in countries without freedom of the press.” Their project proved how liberating technology can be for humanity and that we too could be a part of the movement.

Weeks later, during our times of social distancing, PVD Young Makers staff and interns came together to recreate the sense of belonging we experience weekly in Providence Community Library locations. We embarked on a mission to keep in contact with each other and library patrons by creating a new way to meet up, share ideas and make progress together.

Debbie Adekunle, PVD Young Makers Intern and Classical High School Junior says:

“This project is important because it will eventually allow us to connect with our PVD Young Makers (students) and provide a resource that is both intellectual and helpful with connecting with friends and families we can’t see during these trying times. It can also be an escape from this tough reality for many students or the highlight of their days because right now their days are basically online school and interacting with the same people.”

Welcome to PVD Young Makers Minecraft Realm- a place where we build together, create weekly design prompts, share notes and express our personal styles through original architecture.

Shown here are two of PCL’s neighborhood libraries: Washington Park Library and Olneyville Library. Inside of Olneyville Library (below), PVD Young Makers Intern & Freshman at Classical High School, Richard Orellana, built a makerspace that accurately represents Olneyville’s makerspace in real life- fully equipped with tool cabinets, storage closet and even a 3D printer.

“I think the best part is that there is basically no learning curve. You can kind of just do anything you dream of. Of course, there are still little tricks and optimizations and stuff, but none of it is necessary to enjoy the game.” – Richard Orellana

A huge shout out to Richard from the PVD Young Makers Staff! Richard spent time educating our staff on how to play the game via Google Hangouts – he also provided us links with resources to learn more. We are extremely excited to experience inter-generational learning within this game as us adults learn more and more from our tech-savvy youth.

Another shout out to Andrea Gonzalez for reminding us to stay kind and positive during these times. Click here for a tour of her latest creation.

Andrea Gonzalez, PVD Young Makers Intern and Providence Classical High School Senior created “Rainbow Kindness Tower” (above) – a place where staff and interns can share their favorite music, spawn (breed) their favorite animal, and write what they love about each other.

When asked, “Why is this project important?” Andrea wrote:

“As PVD Young Makers, we are always focusing on personalized learning. We have been with our students for so long, they have become family to us. Some of the kids that come to the libraries don’t have as many activities at home, they have their best friends in the library, and they have trusted adults as well as teens that they can talk to when they are sad. As an educator and a friend, I miss my students, I care for them and wish we could all be learning and doing activities together again. I think this will be a wonderful opportunity, since not only will we be able to teach in new ways, but we will also encourage them to enjoy a new way of learning while having a lot of fun. The Minecraft community is quite popular in the libraries and I think we will all grow together and get through this.”

IT Director David Sok and Assistant Mike Crispino moderate PCL’s Minecraft World (minecraft.provcomlib.org) and created an option to warp to a PVD Young Makers World (/warp PVDYM). Creating this Minecraft world requires constant troubleshooting and we are lucky to have these two techies on our team! PVD Young Makers staff Francesca DelPrete and Keith Ranaldi will continue meeting weekly with PVD Young Makers interns to brainstorm how we can utilize this world to tell our story and connect with community members during times of social distancing.

This article is meant to showcase our work in progress and most importantly share student voices. We hope to be able to share more with the public as we move through the design process. Stay tuned for more updates on how our Minecraft Realm grows!

Written by Francesca Del Prete & Keith Ranaldi with words from highschool students Debbie Adekunle, Richard Orellana & Andrea Gonzalez

FabNewport & PVD Young Makers Staff Produce Face Shields in Response to the COVID-19 Pandemic

Since the start of the COVID-19 pandemic, FabNewport and PVD Young Makers (PVDYM) have been at the forefront of designing, creating and distributing Personal Protective Equipment (PPE) for medical and healthcare workers fighting the virus in Rhode Island.

As soon as it became clear that there was a shortage of PPE for our medical workers, we began researching ways that we could help and reached out to other makers and engineers. As a community-based makerspace, we knew we were uniquely positioned to make an impact during this time. We began by reaching out to other groups and organizations that were also interested in helping to solve the problem of PPE shortages. We have since become part of a working group of schools, makerspaces, and private makers who all share the same goal of creating and providing safe and effective PPE alternatives during the COVID-19 epidemic.

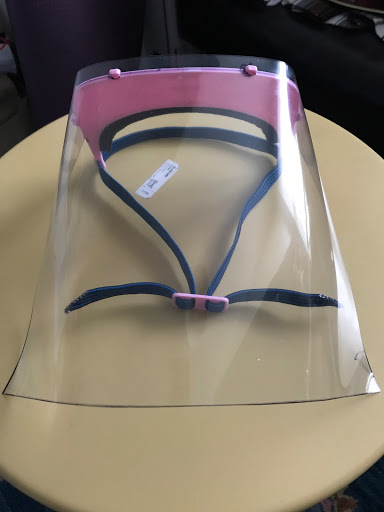

As part of the URI-COVID-19-Rapid-Solvers Google Group, we have been able to pool the resources, knowledge and manpower of the RI Maker Community to source materials, prototype and test designs, and identify the best places to donate/distribute our PPE. The two main types of PPE being created by the URI group are face masks and face shields. FabNewport/PVDYM has chosen to focus on the production of shields. Producing face shields makes more sense for our organization because of the tools and materials we have available. We have been able to produce Face Shields at a much faster rate than if we had tried to produce face masks; and currently there is as much, if not more, need for face shields in Rhode Island.

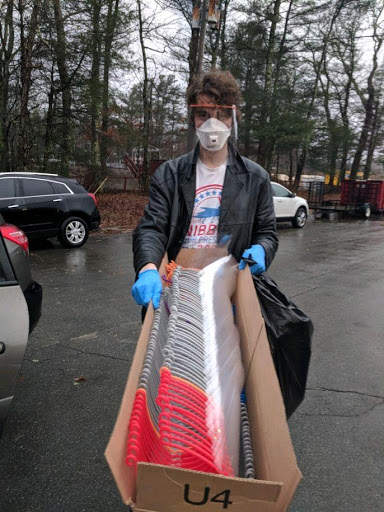

FabNewport/PVDYM owns 13 3D Printers across the state, and we were able to accumulate them all at Rochambeau Library, and have set up a 3D printing factory in the basement while the library is closed. This has allowed us to produce the 3D printed face shield designs at a rapid rate.

So far, there are two 3D printed Face Shield designs that we have been producing. The first is a modified Budmen Design, which has been approved for use in clinical settings by the National Institute of Health (NIH). This design takes about three hours to print, and 30 minutes to assemble. The second design is simpler and much faster to print at around 30 minutes, and can be assembled in five minutes. In addition, the second design does not require any additional materials like the Budmen design; such as foam or an elastic band.

As of April 13th we have donated over 700 face shields, of both designs, to various organizations. The largest donation so far has been around 475 masks which we dropped off with RIDMAT (Rhode Island Disaster Medical Assistance Team). Of the remainder of the face shields already donated, 200 went to Looking Upwards (an at home care organization) and the rest went directly to individuals on the front lines.

Going forward, our goal is to donate about half of the masks we create to RIDMAT, which is the organization tasked with collecting and distributing donated PPE to medical workers/hospitals throughout the state. We would like to distribute the other half of our future face shields directly to organizations on the front lines, such as police, fire, EMS, nurses and other working in our hospitals. We have had many such organizations reach out to us directly requesting PPE.

We are continuously modifying our design, and production methods, to increase the speed of production and to better meet the needs of the end users. After our first donation to RIDMAT, they recommended we stick to the simpler design, and that we include assembly and reuse instructions. Currently, we are in the process of switching all of our production over to the simpler design, and making additional adjustments to make the production process easier and more uniform. For instance, we changed our design from a 6-hole punch, to a 3-hole punch, so that the shields can be produced using a standard 3-hole punch for a 3-ring binder, rather than a custom hole punch. This will allow for anybody to produce additional Face Shields so that the 3D Printed Visor Piece can be easily reused.

With the streamlining of our designs and production techniques our current production estimates are between 80-100 Face Shields per day; at a cost of approximately $3.00 per shield.

Written by Seiji Abe, FabNewport’s Lead Technologist with photos from William Fitzpatrick PVD Young Makers’ Tech Assistant